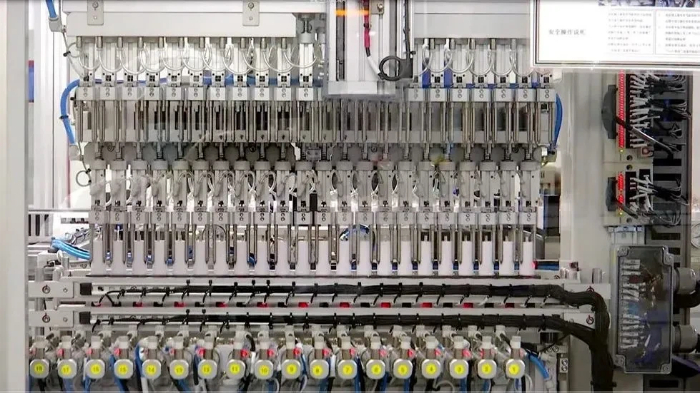

Jiangsu Sunpower. [Photo/WeChat account: gh_07a864197818]

In recent years, Jiangsu Sunpower, located in the Taixing Huangqiao Economic Development Zone, Taixing, Jiangsu province, has promoted a data-driven smart manufacturing strategy, focusing on informatization, automation, and intelligent construction.

The high-tech enterprise is dedicated to the research, development, production, and sales of high-rate lithium-ion batteries.

Intelligent manufacturing is applied across the company's core operations, covering areas such as production plan optimization, process design, equipment management, quality traceability, warehousing and logistics, energy management, and safety and environmental protection.

In the digital workshop of the Phase IV project, Assembly Line 11 produces high-rate lithium-ion batteries at a rate of 300 units per minute, which is 50 percent faster than the traditional production line.

The factory of Jiangsu Sunpower. [Photo/WeChat account: gh_07a864197818]

The company has introduced advanced technologies such as AI visual recognition and X-ray non-destructive testing in quality management, enabling full online inspection and automatic sorting in processes like coating, capacity grading, and assembly.

In addition, by deploying energy management systems and online pollution monitoring platforms, the company is able to closely manage energy consumption and emissions, bringing it closer to its green manufacturing ambitions.